Leading fastener manufacturer from China since 1998

Categories

Contact Us

E-mail:

info@hfastfix.com

Phone/WhatsApp:

+86-18131090805

Address:

Southwest Development Zone,Yongnian District, Handan City, Hebei Province, China.

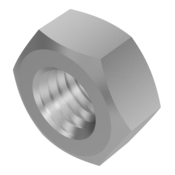

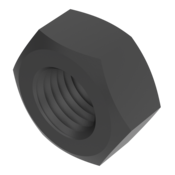

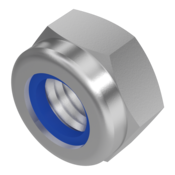

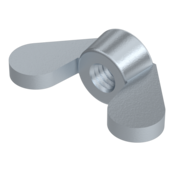

Nylon Lock Nut

Size: M3-M30, 1/4-1''

Material: Carbon steel, Stainless steel

Coating: Zinc plated, Yellow zinc plated, Dacromet, Black, Hot dip galvanizing

Standard: DIN985, DIN982, ASME B18.16.6

- Specification

- Application

- Packing

-

Description

Nylon lock nut, also known as a Nyloc nut, is a type of self-locking nut that utilizes a nylon insert to prevent loosening due to vibration or torque.

Features

★ Self-locking: Requires no additional locking mechanisms like wire or split pins.

★ Vibration resistance: Effective in preventing loosening in high-vibration environments.

★ Reusability: Can be reused multiple times, although locking effectiveness may diminish over time.

★ Temperature limitations: Nylon insert has temperature limitations, affecting its performance in extreme conditions.Dimensions

Size: M3-M30, 1/4-1''

Material: Carbon steel, Stainless steel

Coating: Zinc plated, Yellow zinc plated, Dacromet, Black, Hot dip galvanizing

Standard: DIN985, DIN982, ASME B18.16.6

Grade: 4,5,6,8,10,12Technical Data

Proof load values for nuts with coarse thread Thread

DPitch

P04 05 5 6 8 9 10 12 M5 8 5400 7100 8250 9500 12140 13000 14800 16300 M6 1 7640 10000 11700 13500 17200 18400 20900 23100 M7 1 11000 14500 16800 19400 24700 26400 30100 33200 M8 125 13900 18300 21600 24900 31800 34400 38100 42500 M10 15 22.000 29000 34200 39400 50500 54500 60300 67300 M12 175 32000 42200 51400 59000 74200 80100 88500 100300 M14 2 43700 57500 70200 80500 101200 109300 120800 136900 M16 2 59700 78500 95800 109900 138200 149200 164900 186800 M18 25 73000 96.000 121000 138200 176600 176600 203500 230400 M20 25 93100 122500 154400 176400 225400 225400 259700 294000 M22 25 115100 151500 190900 218200 278800 278800 321200 363600 M24 3 134100 176500 222400 254200 324800 324800 374200 423600 M27 3 174400 229500 289200 330500 422300 422300 486500 550800 M30 35 213200 280500 353400 403900 516100 516100 594700 673200 Production scene

About our company

Hebei Hengcheng Fastener Co., Ltd is a National High-tech Enterprise, established in Hebei Yongnian in 1998, specializing in the production and sales of fasteners including Nuts, Bolts, Drop in anchor, Strong anchor, Self-drilling screw, Self-tapping screw, Drywall screw and Customized cold forging parts. The company covers an area of 70,000 square meters with about 150 staff at present, and among which there are over 30 senior technicians and 30 salesmen. To guarantee the quality, the company applies the world-advanced facilities for production including machines of cold forging,hot forging, threading,wire drawing,annealing,heat treatment and other ancillary equipment. With more than 20 years’ development, the company becomes one of the largest manufacturing enterprises in the fastener industry of North China.

The company has passed the ISO9001:2015 international quality system certification, the trade mark “HF” is honored “Well-Known Trade Mark of Hebei Province”, meanwhile, the product is honored “Famous-Brand Product” by the Authority. The company is an export-oriented enterprise and the products are exported to more than 80 countries and regions, such as South Korea, Japan, America, Southeast Asia, Middle East and Africa and enjoyed a good reputation among customers. The company is dedicated to supply the best products and services to customers and would like to express sincere invitation to friends from all over the world.

-

● Automotive industry

Engine components: Securing bolts and nuts in the engine, transmission, and exhaust systems.

Suspension systems: Preventing loosening of components subjected to constant vibration.

Wheel assemblies: Ensuring wheel studs remain tight.● Construction

Structural components: Securing connections in buildings, bridges, and other structures.

Equipment mounting: Preventing vibration-induced loosening of equipment attached to structures.● Machinery and Equipment

Vibration-prone equipment: Securing components in machinery that operates under high vibration conditions.

Assembly of components: Preventing loosening of bolts and nuts during operation.● Electronics and Appliances

Component mounting: Securing components on circuit boards or enclosures.

Vibration-sensitive equipment: Ensuring components remain securely fastened. -

Regular packing way

★ small box+carton

★ small bag+carton

★ bulk in carton

★ bulk in plastic box

Hot Tags:

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

RELATED PRODUCTS